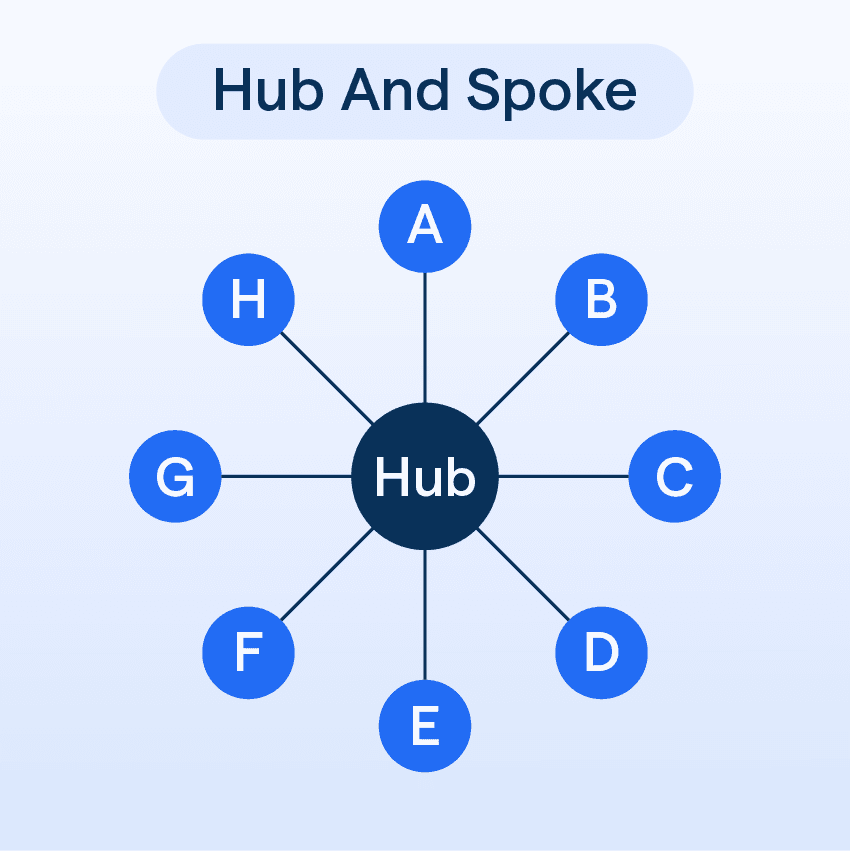

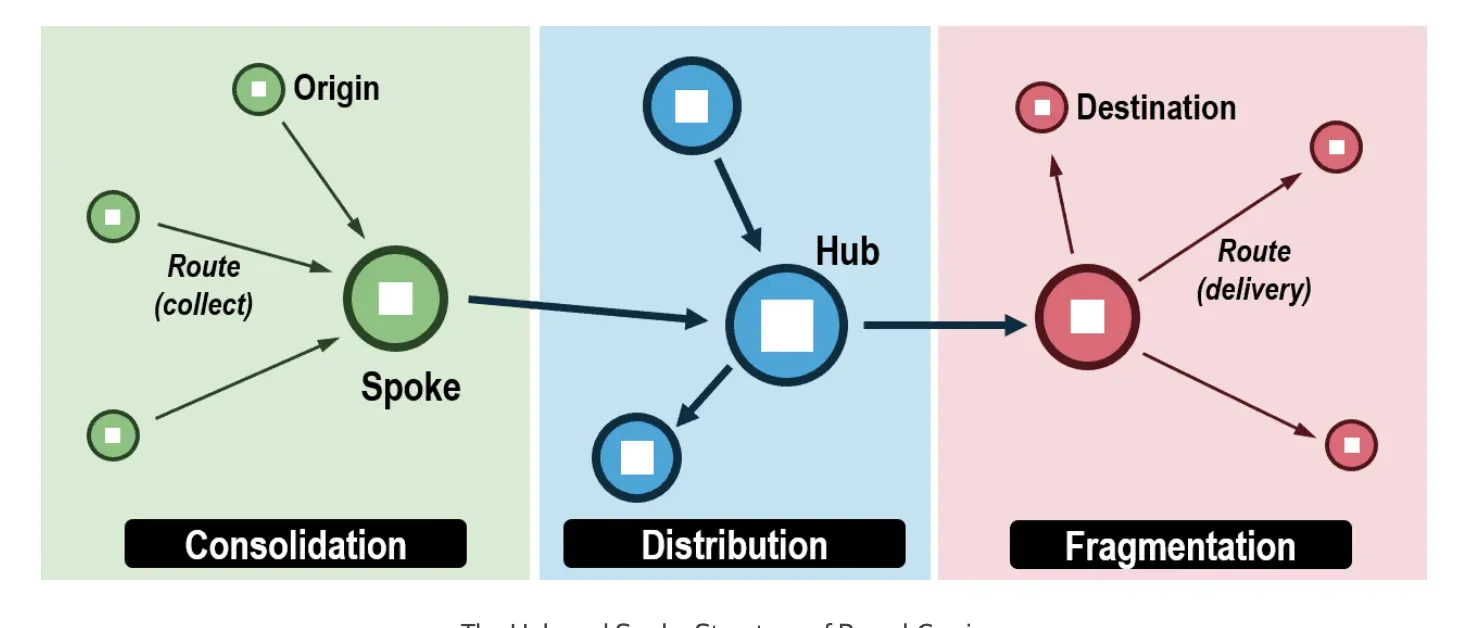

What is Hub and Spoke?

The hub and spoke distribution model is a centralized warehousing and shipment system that bears a resemblance to the structure of a bicycle wheel. The center of the wheel is the hub or a distribution center, and every one of the spokes symbolizes a direction of delivery.

Why do we need the Hub and Spoke Distribution Model?

The hub and spoke distribution model offers several advantages and benefits.

Efficient Last-Mile Delivery Processes

When all shipments are picked up from a centralized hub, it becomes much easier to manage last-mile delivery processes and schedule dispatch. Logistics managers can assign duties systematically and keep track of them with minimum effort.

Optimal Planning of Delivery Routes

The hub and spoke distribution model allows delivery partners to plan their daily delivery routes around one hub, finishing all the deliveries in one specific region before proceeding to another hub for on-demand or extra deliveries.

Cost Reduction in Supply Chain Operations

By ensuring optimal route planning, the hub and spoke distribution model helps reduce costs for supply chain enterprises. The model saves on fuel costs due to fewer miles traveled and limits the number of distribution centers in a city, thus reducing the cost of inventory management.

Environmental Sustainability and Carbon Footprint Reduction

The hub and spoke model, with its optimal route planning, leads to fewer empty miles driven and thereby reduces wasted fuel and emissions. Supply chain enterprises adopting this model can contribute to reducing their carbon footprint.

Hub and Spoke in Different Industries

The hub and spoke model has various applications across various industries. Here’s a detailed look:

Retail's Efficiency Game Changer

In the retail industry, the 'Hub and Spoke' model strategically positions a central warehouse ('the hub') to supply various retail outlets ('the spokes'). This framework enhances distribution efficiency, minimizes delivery intervals and costs, and ensures faster access to products for consumers, boosting overall service quality and profitability.

Putting Healthcare into High Gear

The 'Hub and Spoke' principle is becoming increasingly significant in healthcare. The model allows for a centralized patient database hub, which 'spoke' healthcare providers can access for comprehensive patient data. It greatly improves coordinated care, referrals, and patient outcomes, presenting a more patient-focused health delivery system.

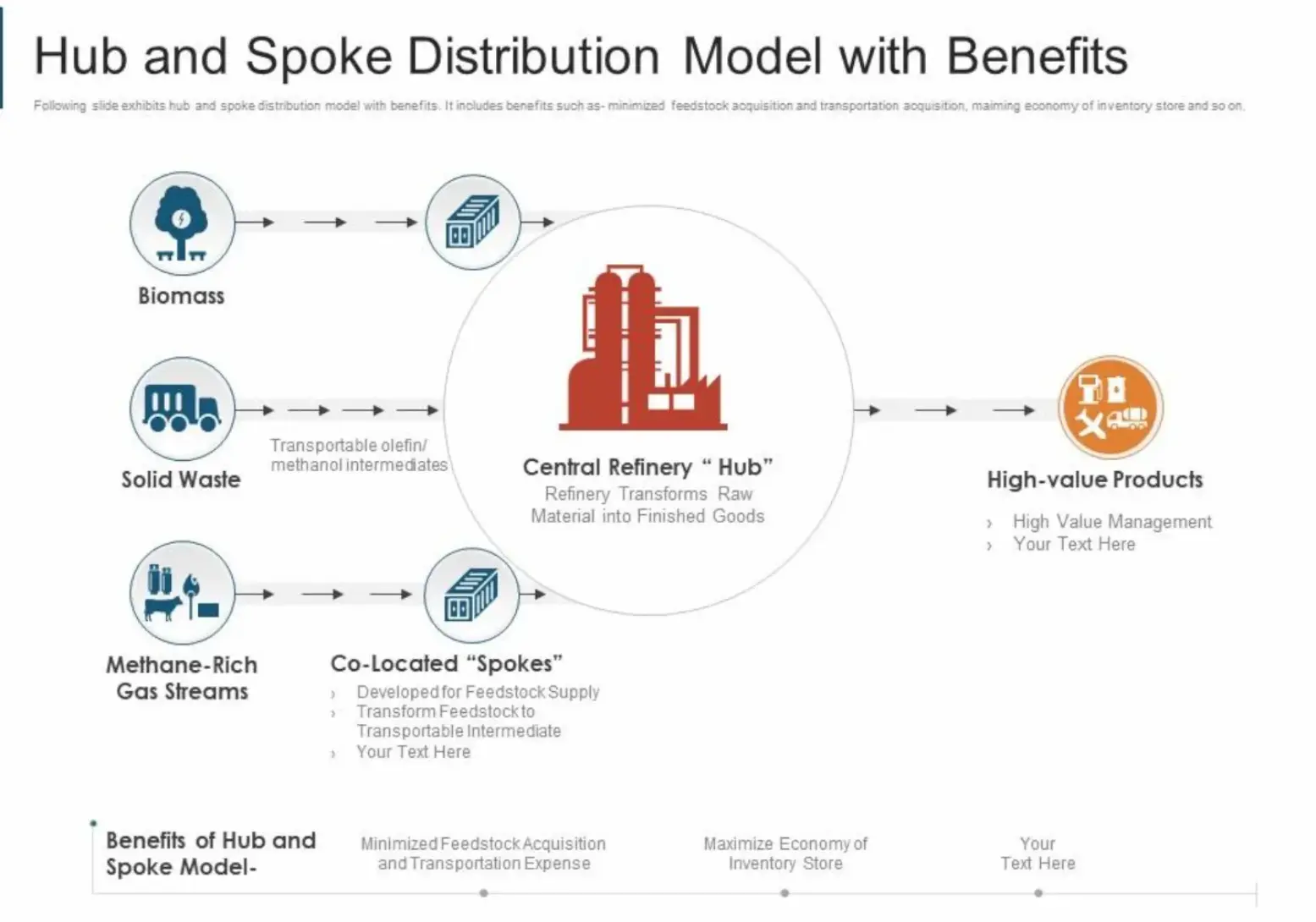

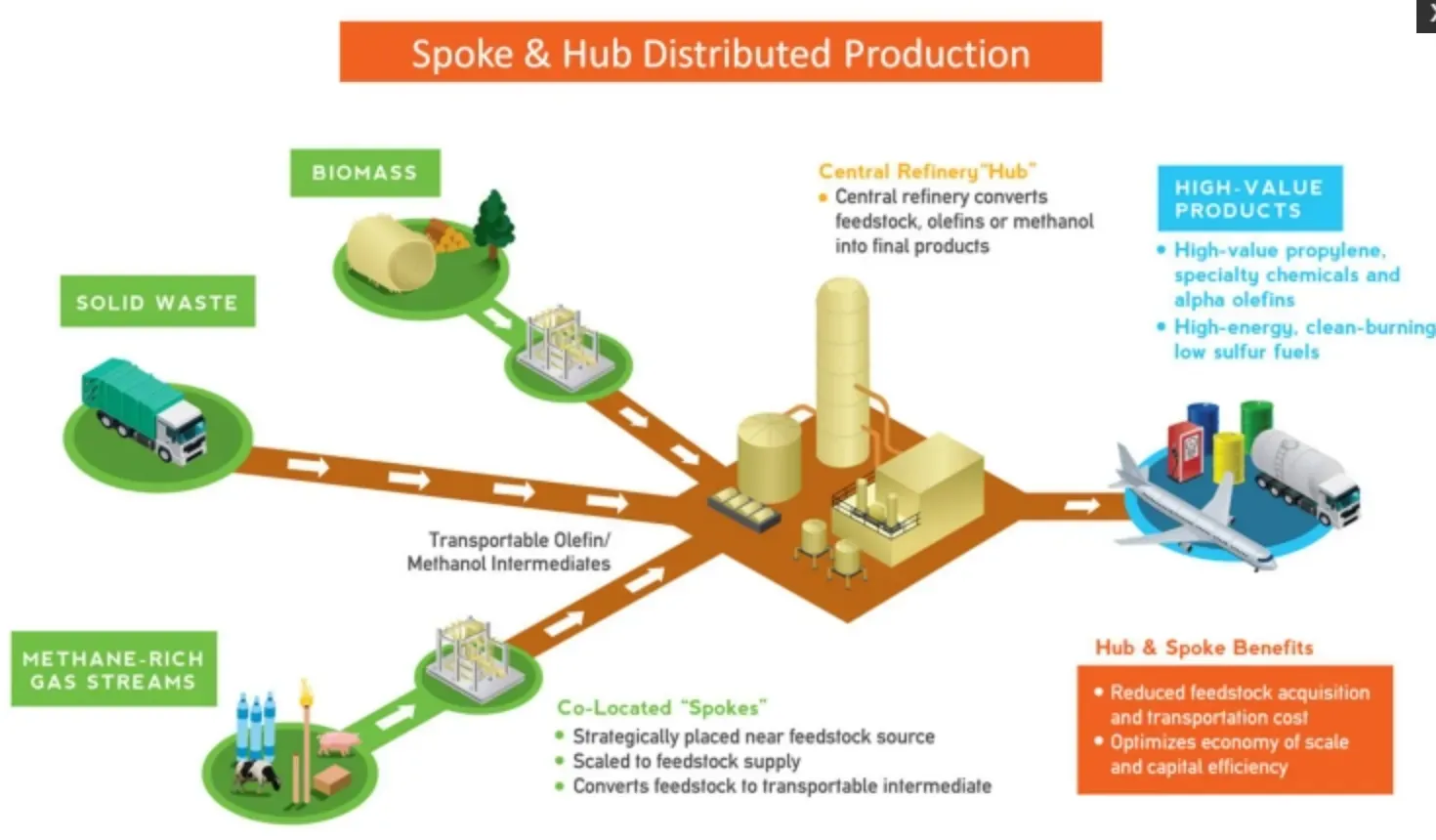

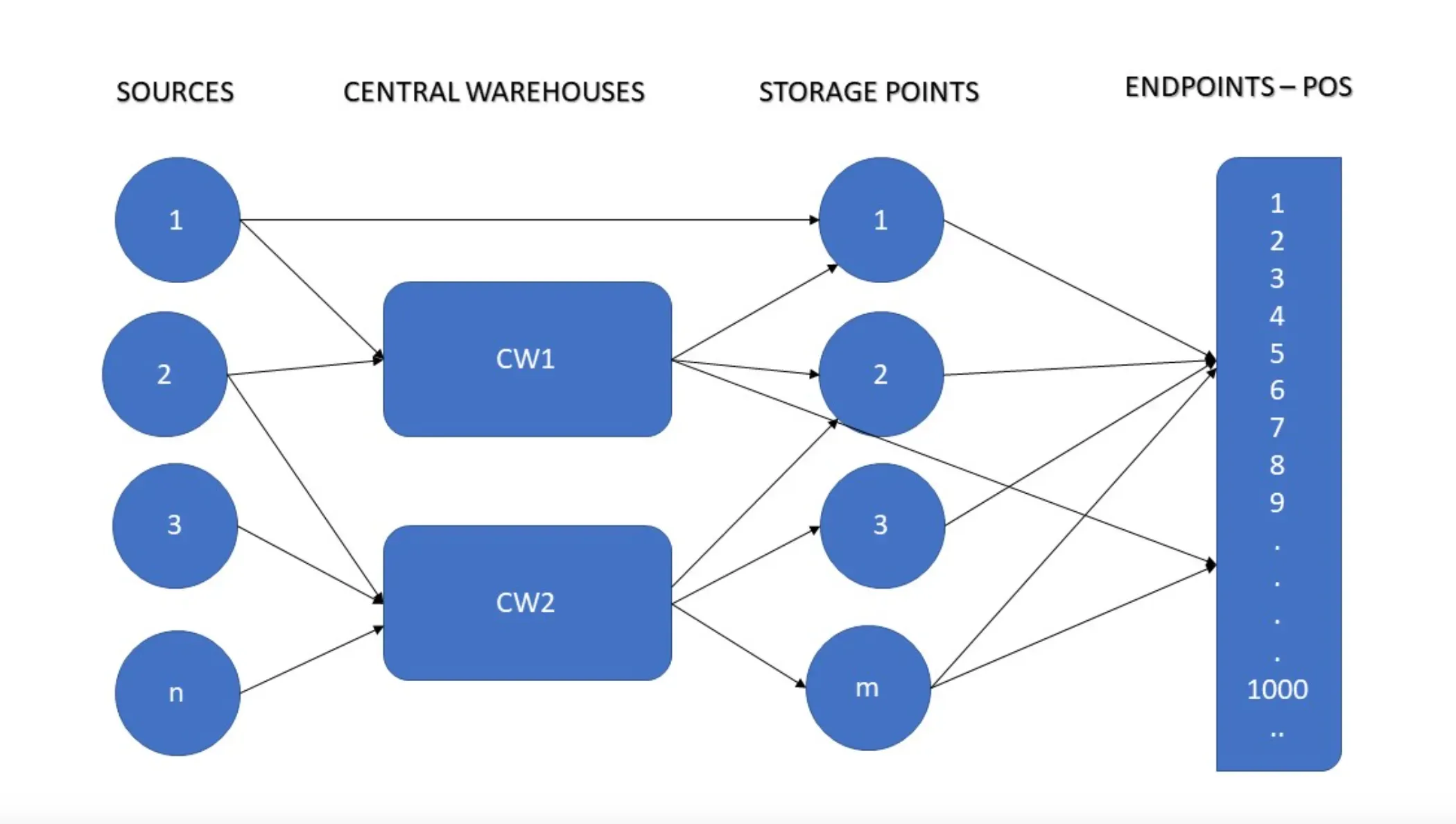

Supply Chain—The Efficiency Backbone

The 'Hub and Spoke' model is transforming traditional supply chain logistics. By centralizing inventory control at the hub and managing the flow of goods to and from the spoke endpoints, supply chains can achieve better product tracking, efficient redirection of goods, and minimized costs while improving delivery times.

Sky High—Aviation Industry Reimagined

The aviation industry leverages the 'Hub and Spoke' model effectively, creating centralized 'hubs' and connecting 'spokes' to various destinations. This structure optimizes network connections, significantly improving operational efficiency, offering extensive route coverage, and enabling passenger transfers with minimal delay, all while keeping costs in check.

The Financial Shake-up

In the financial world, the 'Hub and Spoke' model offers a centralized system for managing operations and risks better. The 'hub' can effectively control, monitor, and streamline operations across disparate 'spoke' branches or units, fostering transparency and agility. Plus, it enhances customer service dynamics by swiftly addressing client queries and issues from a centralized point—even when they relate to operations at various spoke locations.

How to Implement a Hub and Spoke System?

Implementing a hub and spoke distribution system requires careful planning and consideration. Here are some key factors to keep in mind:

Step 1

Location Optimization

Choosing the right location for your hub is crucial. Consider factors such as proximity to major transportation routes, customer demand, and availability of skilled labor. A central location with good access to highways, airports, and rail lines is ideal.

Step 2

Route Planning

Efficient route planning is essential for a successful hub and spoke system. Analyze customer demand patterns and determine the most optimal delivery routes. Use data analytics and mapping tools to identify the best routes that minimize travel time and distance.

Step 3

Inventory Management

Maintaining an optimized inventory management system is vital for the hub and spoke model. Centralize your inventory in the hub and ensure real-time visibility of stock levels across all spokes. Utilize technologies like barcode scanning and inventory management software to track and manage inventory efficiently.

Step 4

Efficient Hub Operations

The hub is the central point of coordination in the hub and spoke system. It is essential to establish efficient hub operations, including smooth coordination between various spokes, streamlined loading and unloading processes, and effective communication. Invest in automation and technology solutions to streamline operations and minimize delays.

Case Studies of Successful Hub and Spoke Implementations

Numerous companies have successfully implemented the hub and spoke model in their distribution systems. Let's take a look at a few examples:

Amazon's Fulfillment Centers

Amazon's hub and spoke distribution system, with its centralized fulfillment centers (hubs) and fast last-mile delivery (spokes), has revolutionized the e-commerce industry. By strategically locating the hubs and optimizing delivery routes, Amazon ensures quick and efficient order fulfillment.

FedEx and UPS

Global shipping giants like FedEx and UPS rely on the hub and spoke model to deliver packages worldwide. Their extensive network of distribution hubs allows for efficient sorting, consolidating shipments, and optimizing delivery routes while maintaining fast and reliable service.

Airlines and Airports

The aviation industry has long embraced the hub and spoke model to optimize flight routes and maximize connectivity. Airlines like Delta and United Airlines have established major hubs at airports like Atlanta and Chicago, respectively, allowing them to efficiently consolidate passengers and cargo while streamlining connections.

Challenges and Limitations of the Hub and Spoke Model

Despite the many advantages of the hub and spoke model, there are also some limitations and challenges to its implementation:

Dependence on the Hub

The hub and spoke model relies heavily on the centralized hub for coordination and management of deliveries. Any technical issues, delays, or disruptions at the hub can cause significant delays and impact the entire distribution system.

Potential Delays

Shipping time can be more prolonged in the hub and spoke model as packages make a stop at the hub before reaching their final destination. Depending on the reliability of the hub and the efficiency of its operations, shipping time frames can be affected.

High Upfront Costs

Establishing a hub and spoke system requires significant capital investment in terms of constructing the hub and spoke locations and adopting new technologies. This upfront cost may be prohibitive for some businesses.

Resource Mismanagement

Managing a centralized hub and multiple spokes can be challenging from a resource perspective. It requires careful tracking of inventory levels, optimizing distribution routes, and efficient availability of staff, drivers, and vehicles.

Mitigating Challenges and Optimizing the Hub and Spoke Model

To overcome these challenges and limitations, companies can take proactive steps to optimize their hub and spoke system's efficiency:

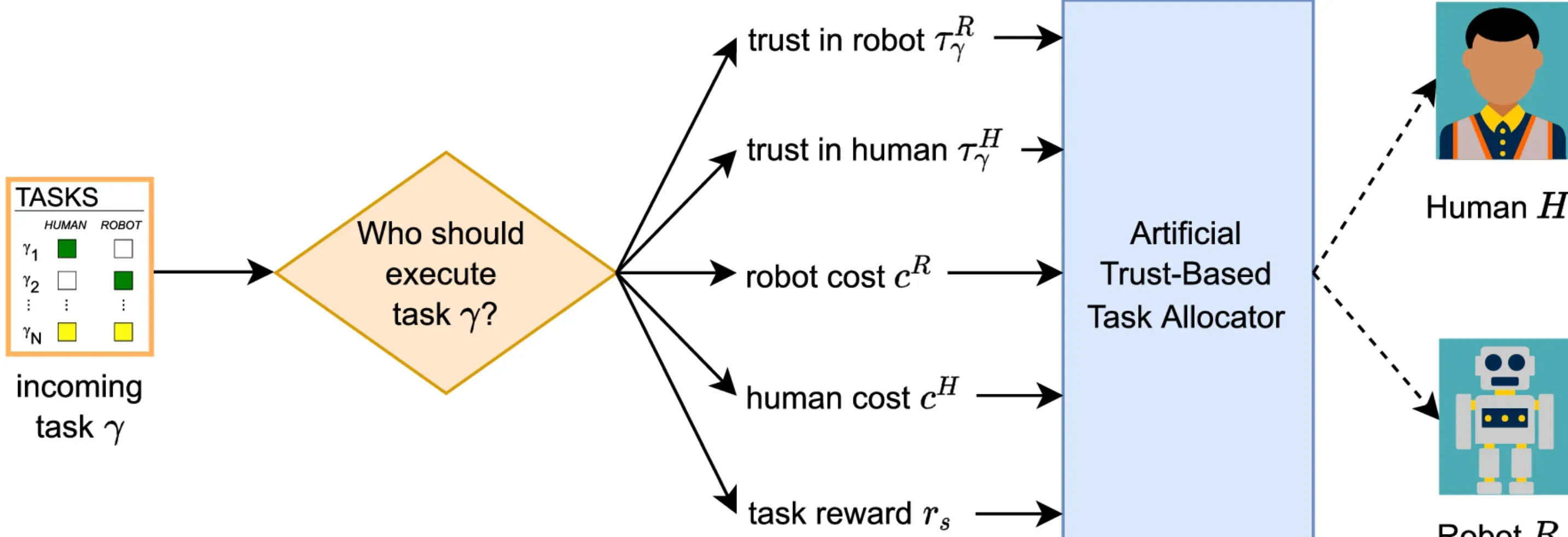

Adopting Technology

Investing in modern technologies like automation, data analytics, and real-time tracking software can streamline operations, reduce delays, and improve inventory management across the entire distribution system.

Partnering with Quality Service Providers

Collaborating with reliable delivery service providers helps ensure efficient operations. Vet and constantly evaluate partners based on their quality of service to ensure they align with your distribution goals.

Implementing Efficient Routing Strategies

Adopting optimal routing strategies that minimize travel distance and time can reduce the overall shipping time and improve service quality.

Focusing on Hub Operations

Centralizing your operations in the hub allows you to optimize the management of resources, inventory, and shipping routes efficiently. By prioritizing efficient hub operations, you can minimize delays and ensure reliability across the distribution network.

Continuously Evaluating Performance

Regular evaluations and performance metrics help identify inefficiencies and suggest data-driven improvements to the system. Use these metrics to optimize your hub and spoke system continually and keep enhancing performance.

Future Trends and Innovations in Hub and Spoke Systems

As technology continues to evolve and advance, the future of the hub and spoke model in logistics looks bright. Here are some technological advancements and automation trends that could enhance hub and spoke networks:

AI and Machine Learning

With AI and machine learning, logistics companies can optimize their hub and spoke systems by predicting demand patterns, choosing the most efficient shipping routes, and managing inventory better.

Robotics and Automation

Automation can streamline operations, reduce labor costs and improve warehouse and distribution center safety and efficiency. For example, robots can handle the picking and packing of packages at the hub and spoke locations, allowing human workers to focus on high-value activities.

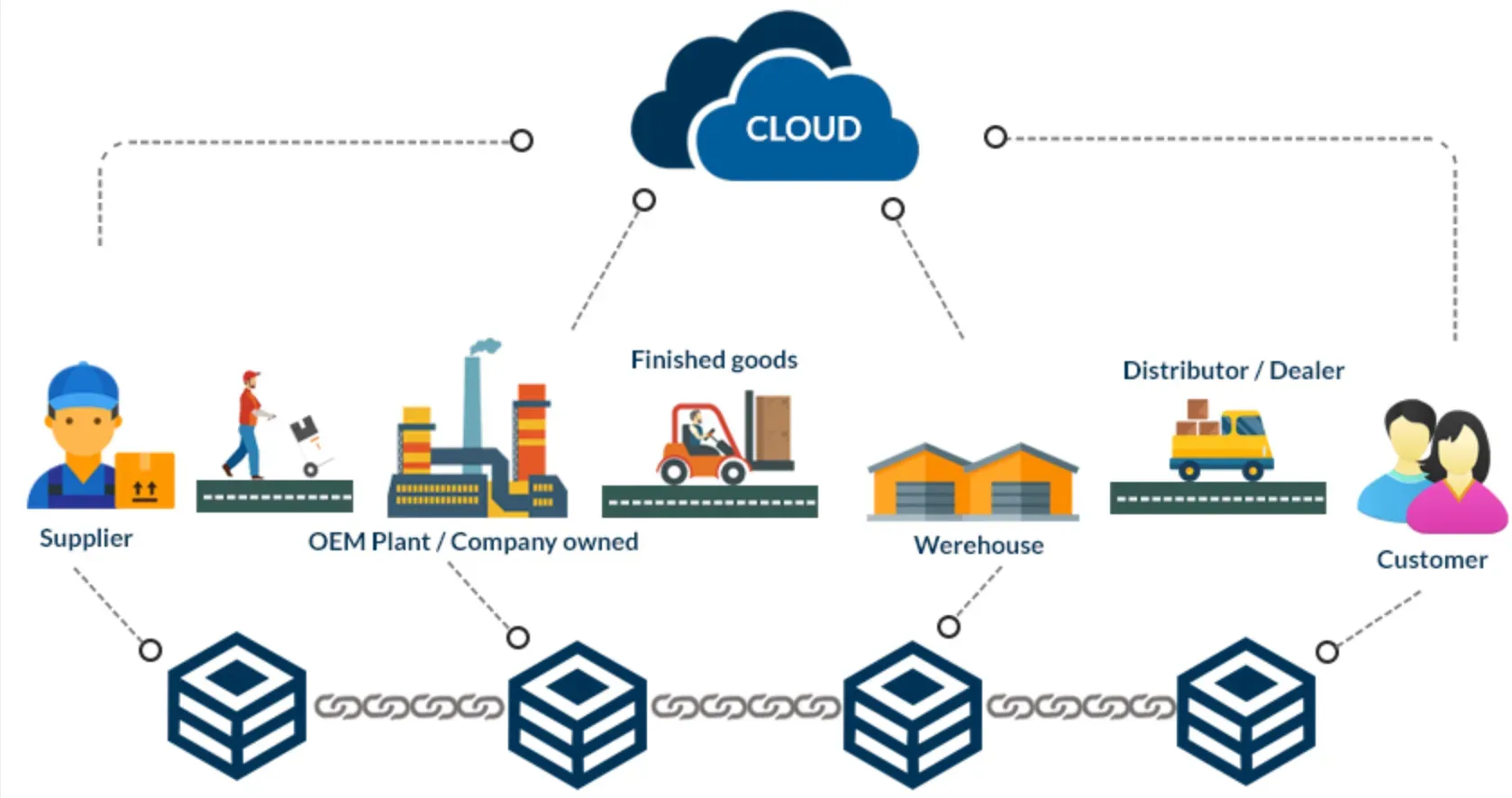

Blockchain Technology

Blockchain technology can enable more transparent and secure tracking of inventory, shipments, and transactions, eliminating the possibility of fraud and human error.

In conclusion, the hub and spoke model in logistics presents various advantages, such as improved efficiency, cost savings, and better service quality. However, it also comes with challenges, including dependence on the hub, potential delays, high upfront costs, and resource management complexities.

Overall, the hub and spoke model will continue to play a significant role in the logistics industry, enabling businesses to meet the ever-increasing demands for timely and reliable delivery services.

Suggested Reading: Blockchain: The Future of Technology

Frequently Asked Questions (FAQs)

What exactly is the Hub and Spoke model in logistics?

The Hub and Spoke model is a popular logistics strategy that involves a central hub or distribution center acting as the focal point for the collection, sorting, and distribution of goods to the spokes - various destinations, often covering a wide geographic area.

How can the Hub and Spoke model reduce logistics costs?

With a Hub and Spoke model, logistics companies can consolidate their inbound transport, inventory storage, and outbound transport, which saves time and resources. This reduces transportation costs and improves delivery times while also increasing inventory accuracy and reducing errors.

Can implementing a Hub and Spoke model reduce transit time?

Yes, a Hub and Spoke model can reduce transit time by optimizing transport routes, reducing transportation costs, and improving inventory accuracy. The centralized hub enables logistics companies to track shipments closely and compensate for any delays quickly.

Does the Hub and Spoke model impact delivery service quality?

The Hub and Spoke model can improve delivery service quality if implemented correctly. Centralizing resources in the hub and optimizing routes can enhance customer service levels and ensure timely deliveries. However, disruptions at the hub can impact the entire distribution system, leading to lower service quality.

How can technology improve the Hub and Spoke model?

Technology like Artificial Intelligence (AI), Machine Learning (ML), Robotics, and blockchain can enhance the Hub and Spoke model's efficiency. These technologies can streamline operations, optimize shipping routes, and manage inventory better, making the system more reliable, productive, and cost-effective.