What is a Stockout?

A stockout happens when a business runs out of a product that customers want to buy. This can take place in physical stores or online. Stockout occur due to poor inventory management, unexpected spikes in demand, or delays in supply.

When the Stockout happens, customers leave empty-handed, and businesses lose out on potential sales. For example, if a retail store doesn't restock a popular product quickly enough, customers may purchase from competitors, leading to lost opportunities.

Importance of Preventing Stockout

Preventing stockout is crucial for keeping customers happy and protecting your business’s bottom line. When businesses avoid stockout, they ensure smooth operations and maintain customer trust. Here's why stockout cost prevention is important:

- Customer Satisfaction: When customers visit a store or an online shop, they expect the items they want to be available. A stockout cost leads to disappointment, and frustrated customers are more likely to shop elsewhere, reducing customer loyalty.

- Revenue Protection: Each stockout represents missed sales. Over time, these missed opportunities can add up and result in significant revenue loss. Regular Stockout can affect profitability and hurt the long-term financial health of a business.

- Brand Trust: Customers rely on businesses to provide products when they need them. Repeated stockout may cause customers to lose faith in a brand, seeing it as unreliable. Maintaining stock levels helps uphold the brand's image.

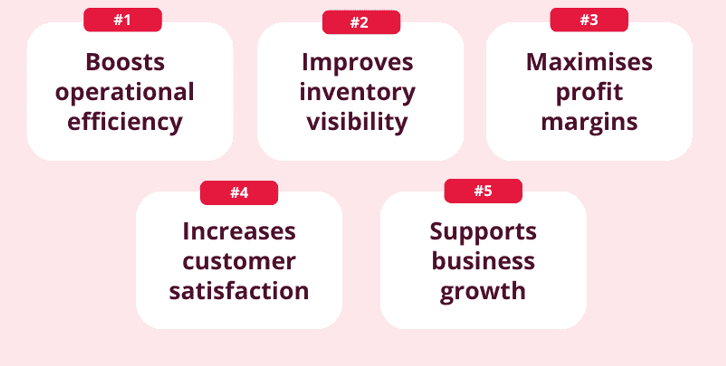

Benefits of Managing Stockout Effectively

Managing stockout properly brings clear benefits to businesses, leading to better performance. Here are the key benefits of effective stockout cost management:

- Cost Savings: Managing inventory efficiently helps prevent overstocking and understocking. Overstocking increases storage costs, while stockout leads to missed sales. Effective stock management helps businesses save money by reducing unnecessary expenses.

- Customer Retention: Ensuring product availability improves the customer experience. When customers can rely on your store to have the items they need, they are more likely to return for future purchases. Happy customers become repeat customers, boosting retention rates.

- Improved Inventory Control: Effective stockout cost management allows businesses to track inventory accurately. By understanding which products are in demand and when, businesses can plan their inventory better and avoid the risk of running out of stock.

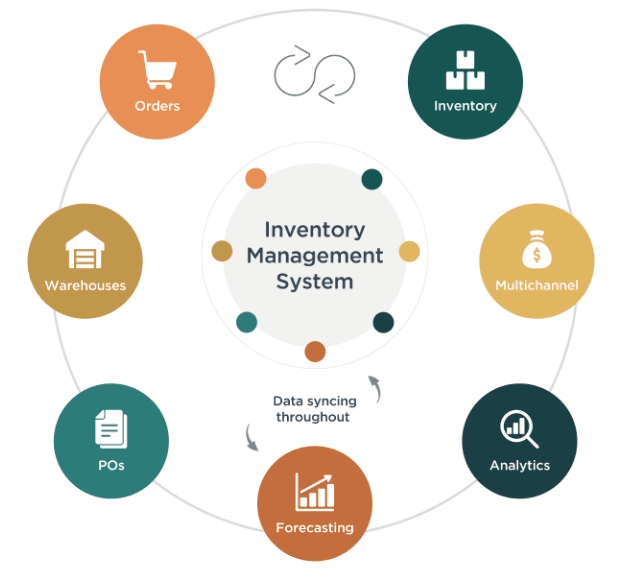

Role of Technology in Preventing Stockout

Technology has become a critical tool in preventing stockout. Businesses today use software and analytics to manage their stock levels and avoid running out of products. Here’s how technology helps:

- Inventory Management Systems: Software solutions help track stock levels in real time. These systems monitor when stock is running low and can even trigger automatic reordering.

This ensures that businesses always have the right amount of inventory on hand.

- Automated Reordering: Many inventory systems allow for automated reordering based on sales trends. Businesses don’t need to manually monitor stock levels.

The system detects when an item is close to being out of stock and places a reorder before a stockout occurs.

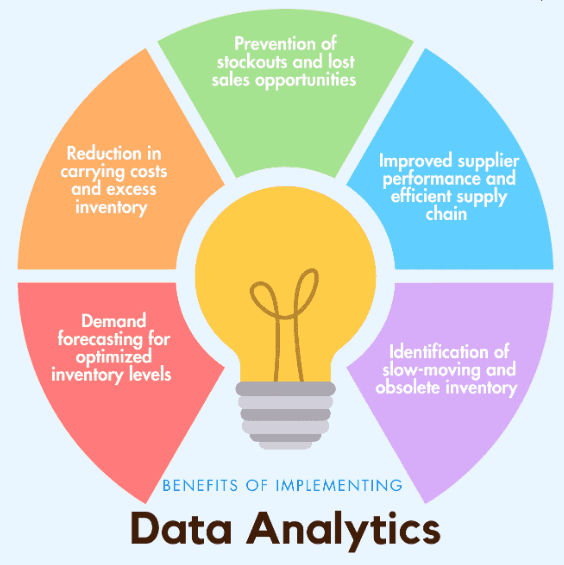

- Data Analytics: By analyzing sales patterns, businesses can predict future demand. This information helps in stocking the right products at the right time.

Predictive analytics allow businesses to plan ahead and avoid the Stockout during peak seasons or unexpected spikes in demand.

Use Cases of Stockout Prevention

Different industries have their own unique challenges when it comes to managing stockout. Here’s how stockout cost prevention applies to three major sectors:

- Retail Industry: Retailers need to ensure they have popular items in stock, especially during high-demand seasons like holidays.

For example, if a clothing store runs out of a best-selling shirt, customers may not wait for restocking and could buy from a competitor instead. Preventing Stockout ensures customer satisfaction and higher sales.

- E-commerce Businesses: Online stores face stockout cost risks across multiple channels and locations. For example, if an online store runs out of stock in one region, it could lose customers from that area.

By using inventory management tools, e-commerce businesses can prevent Stockout and maintain customer trust across their platform.

- Manufacturing Sector: Manufacturers must ensure they have enough raw materials to keep production running smoothly. If a factory runs out of a key material, production halts, causing delays.

Preventing the Stockout of raw materials ensures that manufacturing schedules stay on track and customers receive their products on time.

Frequently Asked Questions (FAQs)

What is a stockout?

A stockout cost occurs when a business runs out of inventory for a product that customers want to purchase, leading to missed sales and customer dissatisfaction.

How does a stockout affect businesses?

Stockout leads to lost sales, unhappy customers, and damage to a brand’s reputation. Repeated Stockouts can cause long-term revenue loss and reduce customer loyalty.

How can Stockout be prevented?

Stockout can be prevented by using inventory management software, tracking sales trends, and implementing automated reordering systems to ensure products are always available when needed.

What are the main causes of Stockout?

Stockouts are typically caused by poor inventory management, unexpected increases in demand, supplier delays, or errors in forecasting product needs.

What industries are most affected by Stockout?

Retail, e-commerce, and manufacturing industries are most affected by Stockout. Any business that relies on product availability can suffer from missed sales due to Stockout.

How does technology help prevent Stockout?

Technology like inventory management systems, automated reordering, and data analytics helps businesses track stock levels, predict demand, and prevent Stockout by optimizing inventory